By Jenni Wirtz | 29 March, 2019

The History Of Borg & Beck

In 1903, iconic brands such as the Ford Motor Company, Harley Davidson and Atletico Madrid were established, Vauxhall began vehicle production, the Wright Brothers took their first flight and the inaugural Tour de France was held. This was also the same year Borg & Beck was founded.

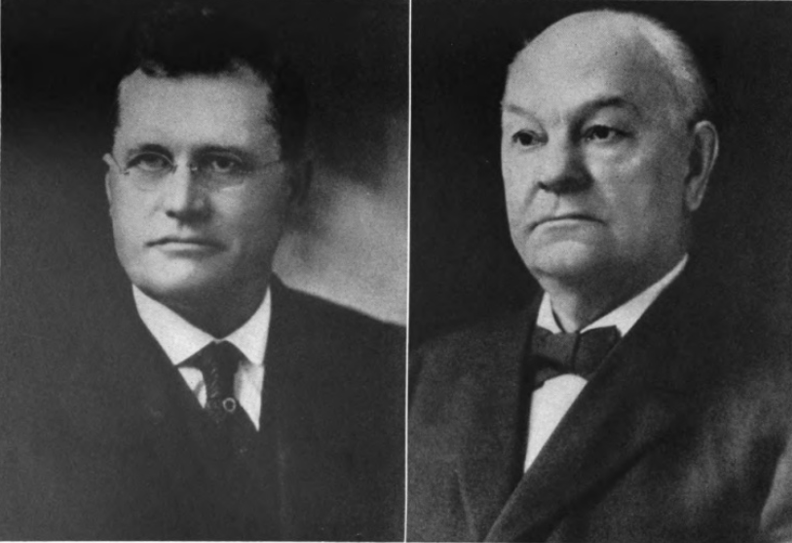

In Moline, Illinois, Charles Borg, a mechanical genius, and Marshall Beck, an inventor, joined forces to set up the Borg & Beck Company. Originally, the company was set up to develop, amongst other things, automatic machines for making wagon poles for carts, which at the time was a 15-part manual process.

In that decade, the rise of automobile manufacturers began and in the same town there was a manufacturer, called Velie. In the Spring of 1909, an engineer from Velie asked Charles’ son, George, what he knew about clutches, which was only that they were a component for an automobile. This came as no surprise as they were generally only understood to be a constant source of trouble!

After a brief explanation, the engineer gave George a blue print of a clutch, focussing his attention on the cover. He went on to explain the troubles they’d had with their existing suppliers, which was disrupting vehicle production and asked whether George could step in and cut a male thread on the inner casting. George foresaw a great opportunity to be part of the growing automobile industry and suggested they send them the castings.

An hour following the meeting, the castings were delivered, and George asked his machinist, Gus Nelson whether he could do it. As they were of about 14-inch diameter and needed 32 threads per inch, the job certainly wasn’t an easy task, but within a couple of hours, the clutch covers were complete, and the threads were perfect.

The next day, with his quotes for future orders all prepared, George delivered the covers and on inspection, Velie’s engineers said it was one of the best jobs they’d seen. Already thinking about all the profits that could be made, George was stunned when Gus explained that, while he was happy to help out with the samples, he was a toolmaker and he couldn’t spend every day at a lathe. Having already committed to the job, he asked his other machinists to carry out the work. Although their skills were no match for Gus’s and the work was slower, after some failed attempts, the monotonous work was completed, albeit without making the anticipated profits!

Sometime later, after picking up the Velie blue print for the 50th time, George had an inspiration. He called Marshall Beck and explained that as the company was in financial trouble and the average machinist wasn’t good enough to cut the threads in the covers, they’d just have to design a new solution to the existing clutch. Having identified that the main problems were the rapid wear of the facings, uneven grab and slip, which is when they then burn out, George, Marshall and Gus worked day and night on their alternative clutch system.

From paper designs came wooden patterns, then castings from a foundry next door and, finally, a completed sample lay on the bench in front of them. Gus fitted it with a pair of short shafts, clamped one end into a lathe chuck and attached a pulley to the other. From the pulley he ran a belt to the drive of a machine and connected a steel lever to a separating ‘fork’, so it could be operated by hand. George turned on the power, Gus released the lever, a spring pushed the facings forward compressing the discs and the machine began to spin.

These three men, who had never ridden in an automobile, let alone driven one, had invented the first practical sliding clutch for a motor vehicle!

As this was just a prototype it had to be further developed and tested, so George asked his father if they could get an automobile. However, without sufficient company funds, George bought his own second-hand one, which had to be delivered as he didn’t drive!

After dismantling the existing clutch, Gus machined some connections and installed the new clutch. As none of them had ever driven before, the decision about who was going to drive for the historic experiment was made by the toss of a coin and Gus was selected. After consulting the manual to see how to fire it up, he pushed down the pedal and put the car into gear. As he let in the clutch, the car took off and crashed into a brick wall!

Although winded, Gus was unhurt, but as history testifies, the clutch worked!

From here Borg & Beck went into manufacturing the clutch, with the first purchaser being Thomas B Jefferey company of Kenosha, Wisconsin, who needed a solution for the Jeffery Quad, a four-wheel drive truck used by the military. On the verge of losing the contract to supply military vehicles due to significant clutch problems, the Borg & Beck clutch was to be their saviour, replacing the unreliable cone clutch set up. This new Borg & Beck clutch proved itself on all terrains, lasting in excess of two years, which in those days was totally unheard of. Their 40 orders a day, steadily increased up to 100 and Thomas B Jeffery Company then went on to fit Borg & Beck to other automobiles.

In 1931, the Borg & Beck Company Limited was set up by Automotive Products in the UK to manufacture clutches under American patents from Borg & Beck in the USA. This allowed the company to sell British made Borg & Beck clutches in Great Britain, overseas British possessions and the British Empire (except Canada).

The company became the UK's leading manufacturer and supplier of clutches, manufacturing more than four million clutches a year during the 70’s. During that period, in excess of 85% of British made vehicles were manufactured with a Borg & Beck clutch, many of which are still being kept on the roads today by classic enthusiasts.

In 2006, Borg & Beck was purchased by First Line Ltd, who have invested heavily in new product development. Today, Borg & Beck is proud to offer a comprehensive range of clutches for British classics, catering for over 250 applications, the range of more than 40 kits and 75 component references enables the enthusiast to install the brand the vehicle was originally fitted with.

The Classic Clutch range is just a small, but important part of the overall Borg & Beck offering. With an extensive range of over 37,000 references, across 60+ product lines, Borg & Beck’s portfolio is one of the most comprehensive in the aftermarket for car, LCV and CV, old and new. Plus, all products are backed-up with a comprehensive 2-year warranty against manufacturing defects for complete peace of mind.